Corelube Equipment is at the leading edge of technological advancement in the field of wireline cable cleaning with its air wiper and wire cleaner technology. Wireline cable plays an essential function in numerous industries such as oil and mining, telecommunications and mining. They are exposed to harsh conditions and are subject to high demands. The longevity of wireline cables and their performance are contingent on their ability to be properly cleaned and shielded from corrosion and wear. The cutting-edge products of Corelube Equipment have changed the ways of caring for wireline cables by establishing new standards for maintaining and preserving them.

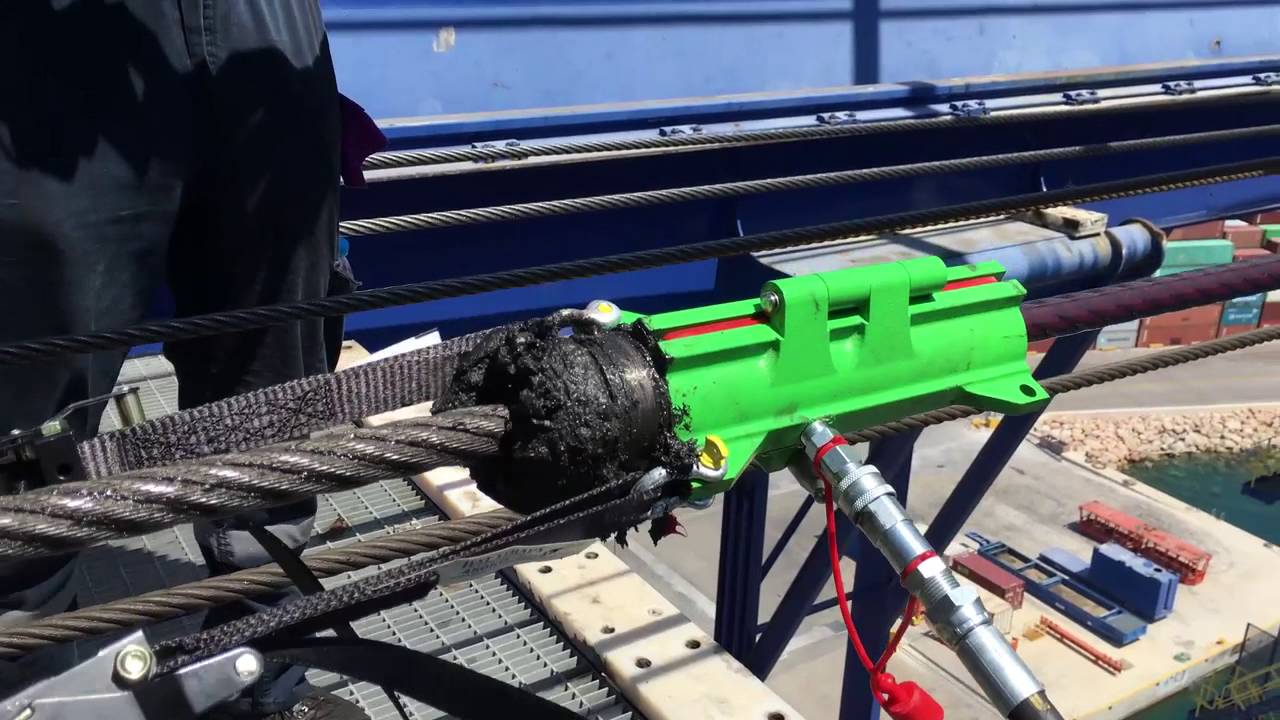

Corelube’s new technology for cleaning wire is an innovation in the field of cable maintenance. Corelube Equipment revolutionized wireline cable preservation by tackling the vital task of cleaning the wire. Dirt, debris and contaminants can affect the structure of wireline cables. Corelube wire cleaners are made to remove impurities and contaminants from cables, protecting them from wear and corrosion.

Corelube’s Air Wiper Technology is essential for protecting cables from weather and other elements. Air wipers safeguard cables from dirt, moisture, and other external factors which can cause them to degrade over time. Corelube Equipment improves the resilience and durability of wireline cable through the use of air wiper systems.

Corelube’s integration of wire cleaner and air wiper technology has revolutionized cable maintenance. It provides a wide range of solutions that ensure the quality of these vital components. Corelube’s superior engineering can be apparent in the manner it solves the twin challenge of cleaning wire while protecting wireline cables from corrosion and wear. Wireline cables receive an amount of attention that has never ever before, thus extending their lifespan while ensuring dependable performance across a variety of industrial applications.

Corelube’s technologies for wire cleaners will maximize the performance of wireline cables in demanding conditions. Wireline cables endure harsh conditions in a variety of settings, including drilling operations offshore and mining excavations. This requires extensive maintenance. Corelube’s unique approach to cable care empowers industry to reach higher levels in operational efficiency and reliability.

Corelube’s Air Wiper and Wire cleaner technologies are proactive methods for maintaining cables. They prevent wear and corrosion from affecting the strength of the cables. Through regular cleaning and protective measures, businesses can dramatically extend the life span of wireline cable, which can reduce the need for costly repairs and replacements. Corelube Equipment’s proactive maintenance program aligns with growing demands of the market for affordable and long-lasting solutions.

Corelube’s air-wiper and wire-cleaner technologies extend beyond the maintenance of the equipment to include security and environmental issues. Wireline cables play an integral role of various industrial processes and their ability to perform reliably is essential for operational safety and environmental protection. The Corelube technologies, which ensure the purity of wireline cables as well as their safety, contribute to the safety and sustainability of industrial operations by aligning themselves with industry-leading practices and regulations.

In conclusion, Corelube Equipment advanced wire cleaner and air wiper technologies have changed the face of cable care for wireline cables and offer a variety of solutions for cleaning wire as well as protecting cables from wear and corrosion. The integration of these cutting-edge technologies has raised the bar of maintenance for wireline cables, aiding industries in achieving greater operational efficiency, reliability, and safety. Corelube Equipment’s emphasis on technology and proactive maintenance continues to lead the development of cost-effective, sustainable solutions for a wide range of industrial applications.